Have you ever wondered how scrap metal is recycled?

It is a fairly straightforward process that involves the retrieval and processing of scrap metal into a raw material that can be used to produce new goods. What’s great about metals is that they can be recycled repeatedly without their properties being altered or degraded.

Ferrous vs Non-Ferrous Metals

Scrap metals are divided into two categories, ferrous metals that contain iron and non-ferrous metals that do not contain iron. Their differences extend beyond that with both types of metals having their own distinct properties that determine what they are most suited for.

Ferrous metals include steel and iron, which are known for their strength and durability. While, non-ferrous metals include aluminum, copper, lead, zinc, and tin, and are known for being resistant to rust and corrosion.

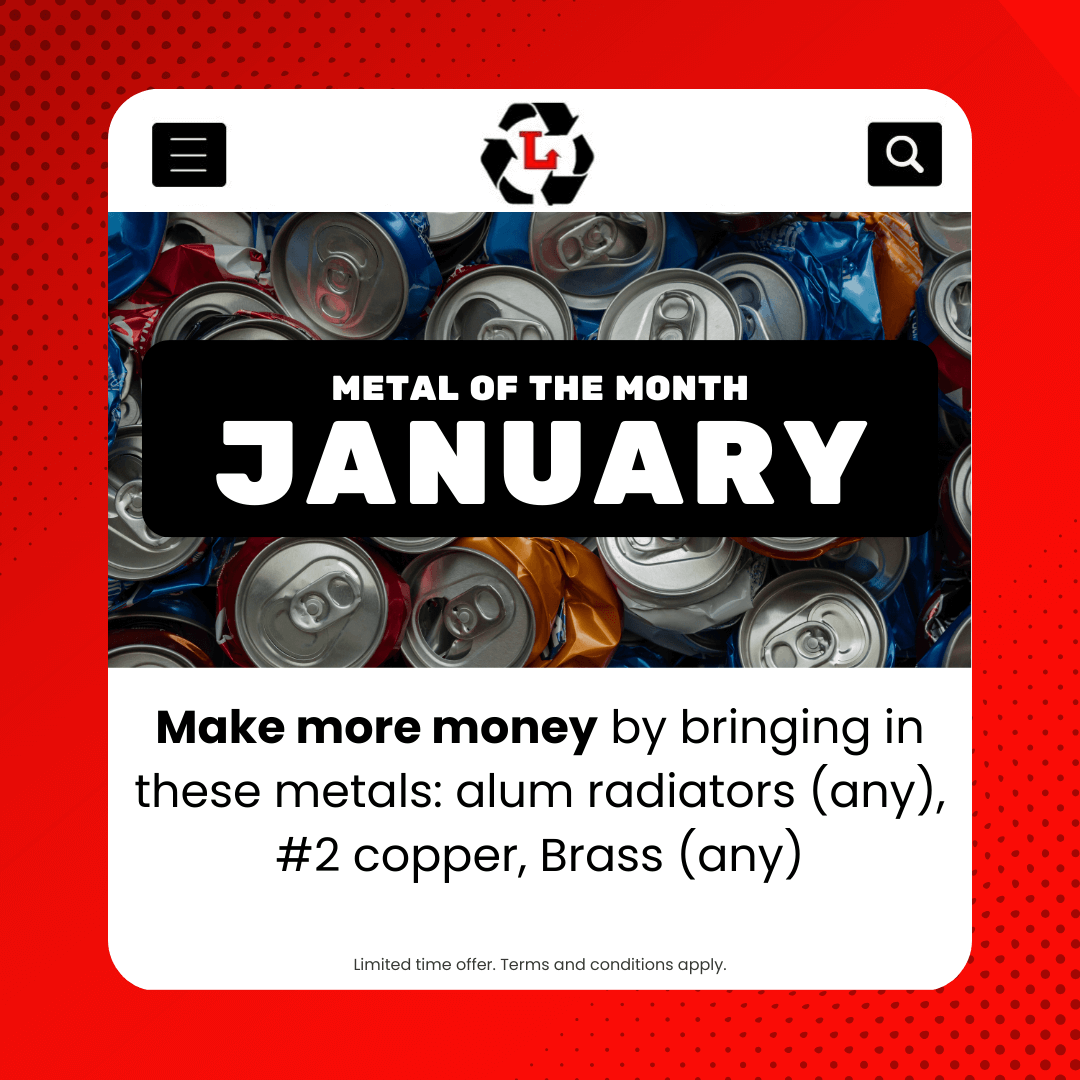

Metals are a valuable material and one of the few recyclable items in which people can collect money from when they recycle them.

The most commonly recycled metals include: steel, aluminium, copper, silver, brass, and gold.

Some Scrap Metal Quick Facts

· Globally, steel production uses up to 40% recycled material

· Annually, up to 400 million tons of metal get recycled worldwide

· Recycling aluminum and copper uses 90% less energy and recycling steel uses 56% less energy than was used to make it originally.

Why Recycle Scrap Metal?

The three R’s (reduce, reuse and recycle) are a key component of environmental-responsibility.

Recycling metal has numerous environmental benefits and economic benefits. Given the high economic and environmental cost of mining metals, recycling reduces pollution and greenhouse gas emissions, saves energy and resources, reduces waste going to the landfill, and prevents the destruction of habitats.

Environmental Benefits

The Institute of Scrap Recycling Industries (ISRI) reported that recycling metal can cut greenhouse gas emissions by 300 million to 500 million tons. It can also prevent chemical leaching, where mercury or other toxins leak into the soil or groundwater.

This occurs because it takes decades for metals to decompose in landfills. According to the U.S. Environmental Protection Agency, if you recycle a single aluminum can, you can conserve enough energy to power a 60-watt light bulb for more than four hours!

Economic Benefits

Recycling scrap metal is economically less expensive than mining for new ore or to obtain new materials. The recycle process also creates new jobs, especially since metals can be re-melted and reshaped continuously. It is a resource that will never be depleted given its ability to be recycled over and over again and contributes to mitigating climate change rather than contributing to the problem.

Recycling metal is important in terms of transitioning into a circular economy, which advises that all things manufactured should be made in such a way that they can later be dismantled and recreated into a final end product once the original product has lost its usability to the consumer.

Benefits to Recycling Scrap Metal

Some common benefits to recycling scrap metal include:

· Emits less carbon dioxide and other harmful gasses

· Saves money and resources

· Allows manufacturing businesses to reduce their production cost

· Creates jobs

· Requires less energy than manufacturing of new products from virgin materials

· It is fast as it only takes 60 days for an aluminum can to be recycled and returned to supermarket

Five Most Commonly Recycled Scrap Metals

The 5 Most Commonly Recycled Scrap Metals are:

1. Iron

Iron is commonly used for pipes, barbecues, and gas heaters. It is known for being corrosive.

2. Copper

Copper is commonly used for electrical equipment, construction and industrial machinery because it both conducts heat and electricity well. It is one of most valuable metals to recycle.

3. Aluminum

Aluminum is the third most common element on earth and is most commonly used for beverage cans. It can also be found in car parts, window pieces, siding gutters, doors and more. It is known for its quick turnaround time from scrap metal to consumer product.

4. Brass

Brass is a combination of zinc and copper and is often used for making light fixtures, bathroom fixtures, faucets, door handles, keys and other plumbing pieces. It is considered a valuable scrap metal.

5. Steel

Steel is commonly used for large appliances, chairs, cars, and shelves. It has magnetic properties, making it one of the easiest metals to recycle. It is one of the most common metals used in manufacturing and is one of the most recycled materials on the planet.

The Value of Recycling Scrap Metal

Scrap metal is one of the most valuable materials that can be recycled. Not only for its environmental and economic benefits, but it can also make you money!

Generally, when scrap metals are returned, there is a rebate associated with it. Scrap metal can come in many different forms but some examples are provided below.

List of Scrap Metal Items

· Copper wire

· Copper piping and tubing

· Aluminum cans (e.g. soda, beans, vegetables)

· Aluminum siding

· Appliances (e.g. refrigerator, range/oven, microwave, washer/dryer)

· Stainless Steel sinks

· Brass plumbing

· Car Batteries

· Transformers

· Backup batteries

· Power outlet bars

Typically, in order to be recycled, the product must be at least 50% metal. That means, as long as most of the product is metal, it can be recycled even if part of it is covered in another material (e.g. plastic). It is best to try and separate the different types of materials the best that you can prior to taking it to a recycling facility.

The Sorting Process

Scrap metal is collected from various locations at a scrap yard where it is then sorted by metal type. Many people are not aware that sorting occurs after putting recyclable goods out at the curb. Materials, especially metals, need to be sorted by type (e.g. aluminum, plastic, paper).

During the sorting phase, scrap metals are put through a radiation detector, shearing machine, shredding machine where metal is cut into very small pieces, ferrous scrap metal separation (separating ferrous and non-ferrous metals), media separation and baling.

During the end of this phase, the ferrous and non-ferrous scrap metal are compacted into large blocks to facilitate handling and transportation.

The recovered materials are melted down in a furnace to produce a quality raw material that can be re-formed into a new material. The melted down material is then poured into casters and shaped into ingots.

The recycled metal also goes through a purification process, which can involve the use of electrolysis, powerful magnet systems or other technologies.

Main Stages of the Metal Recycling Process:

1. Preparing and Collecting

2. Sorting

3. Transportation

4. Melting and Processing

5. Purification

6. Solidifying

7. Transportation of Metal Bars

8. Production/manufacturing of a new product

What Can Metal Be Recycled Into?

The possibilities for recycled metals are endless!

Since recycled metals are melted down, they can be created into anything a new raw material would. Often they are recycled into components for the home, such as furniture, fixtures, lightening or roofing materials or into materials for the construction industry (building roads, train tracks) or the transportation industry (e.g. aircrafts, cars).

The most popular and well-known example is of course the aluminium can. Some recycled metals are crafted into a completely new product, while others are molded into the same product they were originally used for.

Recycling metal saves a lot of material that otherwise would have ended up in a landfill. Recycling scrap metal is necessary for creating a sustainable future, economy and environment.